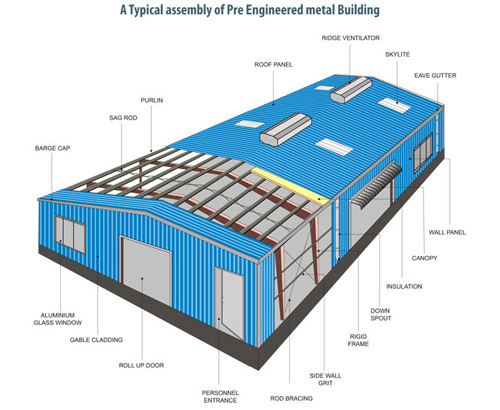

PRE ENGINEERED BUILDING

We offer a complete building system. It starts from engineering, procurement and manufacturing and extends into installing the building along with supplied accessories such as doors and windows.

Basic Building Parameters

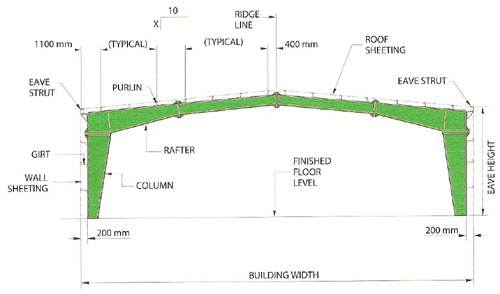

The basic parameters that define a pre-engineered building are: Building Width, Building Length, Building Height, Roof Slope, End bay length, length and Design Loads

Building Width:No matter what primary framing system is used, the building width is defined as the distance from outside of eave strut of one sidewall to outside of eave strut of the opposite sidewall. Building width does not include the width of Lean-To buildings or roof extensions.

Building Length:The longitudinal length of the building measured from out to out of end wall steel lines.

Building Height:Building height is the eave height which usually is the distance from the bottom of the main frame column base plate to the top outer point of the eave strut. When columns are recessed or elevated from finished floor, eave height is the distance from finished floor level to top of eave strut.

Roof Slope (x/10):This is the angle of the roof with respect to the horizontal. The most common roof slopes are 0.5/10 and 1/10. Any practical roof slope is possible.

End bay length:The distance from outside of the outer flange of endwall columns to center line of the first interior frame column.

Interior bay length:The distance between the center lines of two adjacent interior main frame columns. The most common bay lengths are 6 m, 7.5 m and 9 m.

Design Loads:Unless otherwise specified pre-engineered buildings are designed for the following minimum loads:

- Roof Live Load: 0.57 kN/m2

- Design Wind Speed: 110 km/h

Design for snow loads, earth quake loads, collateral loads, crane loads or any other loading condition, if required must be specified at the time of request for quotation.

Loads are applied in accordance with the latest American codes and standards applicable to pre-engineered buildings unless otherwise requested at the time of request for quotation.

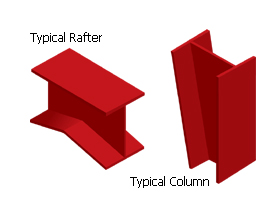

Primary Framing

Pre-engineered buildings are custom-designed to meet your exact requirements. The most common Primary Framing systems are shown below. Practically any frame geometry is possible.

Minimum yield strength is 34.5 kN/ cm2

We can produce other non-standard main frames, of almost any configuration, if required.

High grade steel plate conforming to ASTM A 572M Grade 345. Factory painted with a minimum of 35 microns (DFT) of corrosion protection primer.

Clear SpanBuilding without interior columns - maximum practical width=90m

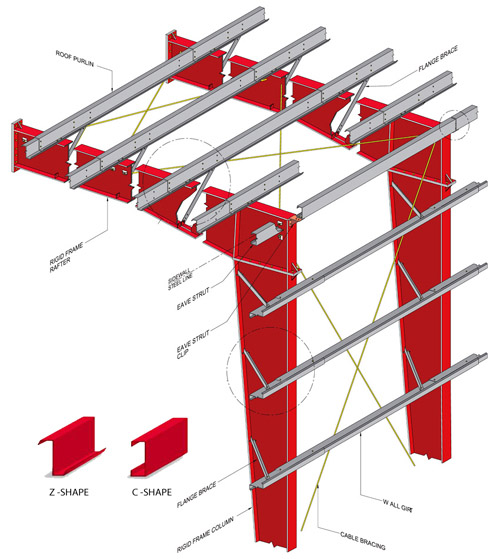

Secondary Framing

Purlins, girts and eave struts are secondary structural members used to support the wall and roof panels. Purlins are used on the roof; girts are used on the walls and eave struts are used at the intersection of the sidewall and the roof.

Secondary members have two other functions:

- Act as struts that help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads

- Provide lateral bracing to the compression flanges of the main frame members thereby increasing frame capacity.

Purlins, girts and eave struts are available in high grade steel conforming to ASTM A 607 Grade 50 or equivalent, available in 1.5 mm, 1.75 mm. 2.0 mm, 2.25 mm, 2.5 mm and 3.0 mm thickness. Pre-They come with a pre-galvanized finish, or factory painted with a minimum of 35 microns (DFT) of corrosion protection primer.

Minimum yield strength is 34.5 kN/ cm2

Applications of Pre-Engineered BuildingsMore than 70% of all single storey non-residential construction, utilizes pre-engineered buildings. The applications of pre-engineered buildings range from small car parking sheds to 90 m (+) wide clear span aircraft hangars to low-rise multi storey buildings. Almost every conceivable building use has been achieved using the pre-engineered building approach.

The most common applications of pre-engineered buildings are:

- Factories

- Workshops

- Warehouses

- Cold stores

- Car parking sheds

- Slaughter houses

- Bulk product storage

- Schools

- Exhibition halls

- Hospitals

- Theaters

- Auditoriums

- Sports halls

- Showrooms

- Distribution centers

- Supermarkets

- Restaurants

- Offices

- Service Stations

- Shopping centers

- Toll Plaza

- Cement Plants

- Steel rolling mills

- Sugar mills

- Ceramic factories

- Gymnasiums

- Swimming pool enclosures

- Indoor tennis courts

- Aircraft hangers

- Administration Buildings

- Residential barracks

- Support facilities

- Poultry-Dairy Farms

- Greenhouses

- Grain storage

- Animal confinement

- Pump stations